Streamlining Electrical Installations in Multistorey Buildings: The Advantages of Prewired Cable Conduit Systems

Electrical installations in public and residential facilities must not only be reliable but also have to meet high safety criteria. At the same time, the current pace of the construction industry requires these large-scale projects to be completed as quickly as possible. Taking into account customer feedback and needs, Pipelife introduced a large range of flexible, prewired electrical conduits a few years ago. The extensive portfolio, which also includes color-coded and halogen-free options, has earned accolades from contractors and installers working on major housing developments in Belgium and abroad.

Saving Wiring Time and Costs

Large construction projects, such as schools, hospitals or multistorey buildings, require complex electrical systems that can be extremely time-consuming to install. And the work starts even before the first cable is laid in a wall. The so-called wiring — pulling kilometers of cables through protection pipes — is a tedious task that receives little love from electricians, especially as wires often get stuck and damaged during the process.

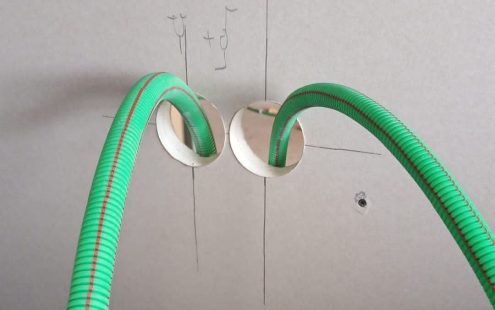

Prewired cable conduits, as the name suggests, are produced with the necessary cables already inserted; the installer just has to cut them to the required length. Thus, there is no need for manual wiring, allowing for the installation to be completed in a much shorter time and with less staffing. Prewired conduit systems also take up less space during transportation and storage while preventing cable damage during these stages.

Reducing Installation Errors and Fire Hazards

Responding to the needs and requests of electrical wholesalers and electricians, Pipelife relaunched its prewired conduits portfolio two years ago — introducing products in seven distinctive colors, one for each cable type.

The color-coded system quickly became a hit among electricians, not only saving the time needed to complete a project but also cutting the risk of installing the wrong wiring to a bare minimum.

Furthermore, the portfolio includes a range of halogen-free prewired conduits for applications where high fire safety is a must. In case of fire, halogen-free materials do not release harmful gases and produce less fumes, which facilitates the safe evacuation of people and animals.

Making Electrical Installations Hassle-Free

Pipelife’s prewired conduit systems are made at the production site in Belgium and meet the EU’s Construction Product Regulation (CPR) Class Cca requirements. Feedback from electricians was a crucial part of the development process, ensuring these conduits are effortless to cut and pull through as well as easily combined with a wide range of complementory wall boxes and fittings.

By now, Pipelife’s prewired electrical conduits have become a go-to option for electricians in Belgium and abroad, especially when it comes to large-scale, fast-paced construction projects where time is of the essence.

Prewired Conduits Help Meet a Tight Timeline

The state-of-the-art student accommodation complex YOU in Leuven was commissioned last year by the real estate developer Polo Architects. The 8,000 m2 building features 104 studio apartments and rooms, each boasting a fully equipped kitchenette.

The electrical installations throughout the complex were taken care of by the installer company Eluxa. As the YOU project had a very tight timeline — students were expected to move in by the fall of 2023 — Eluxa relied on prewired electrical conduits.

According to AREI, Belgium’s General Regulation for Electrical Installations, halogen-free conduits that meet at least CPR Class Cca requirements must be used in hollow walls, and Pipelife’s prewired portfolio offered a perfect fit. Dieter Naenen, Manager of Eluxa, admits that the installers were impressed with how flexible and easy to cut these pipes are. The clear marking by a colored line, indicating the diameter of the wire inside, streamlined the work even further.

“We chose [these conduits] because of their quality, flexibility and ease of installation,” Naenen sums up. “The smooth communication with Pipelife’s employees was another major advantage.”

Top-Tier Electro Solutions for Premium Residential Estate

The freshly completed apartment complex Residentie Rietvink in Tremelo, Flanders, embodies the principles of eco-conscious architecture, blending energy efficiency and modern living conditions.

The project consists of 10 high-end apartments arranged in two blocks, equipped with solar panels as well as underfloor heating and heat recovery ventilation systems.

The electrical installations at Residentie Rietvink were laid by the experienced contractor Electro Corbeels, already familiar with Pipelife’s standard conduits and wall boxes. To speed up the electrification of the extensive housing complex, Corbeels decided to test Pipelife’s halogen-free conduits in the residential areas, whereas classic prewired conduits and flush-mounted wall boxes were used in the communal units.

In total, installers used more than 10 kilometers of prewired conduits alongside ~1000 wall boxes to complete the installation. Fanny Corbeels, Managing Director of the company, is pleased with the reliability and versatility of the system:

“We have recently started working with Pipelife’s prewired conduits because of their quality, convenient color-coding and cost-efficiency.”

Meeting Evolving Expectations

Modern electrical installations, especially in public and residential facilities, must comply with stringent quality and safety standards. Highly reliable conduit systems are imperative to meet these requirements alongside the growing expectations from stakeholders and end-customers.

Using prewired cable conduits has enabled electricians to complete demanding projects in a faster, safer and more cost-efficient way, and Pipelife has been working to bring such systems to the next level.

“As prewired conduits have become essential in today’s fast-paced construction industry, we are proud to have developed and provide premium prewired products that make electrical installations as speedy, safe and reliable as possible,” – Rob van Hoorn, Electro Category Manager at Pipelife.

Find out more about

Get in Touch

Please choose your preferred way to get in contact with us. We will get back to you as soon as possible.

Fill our form