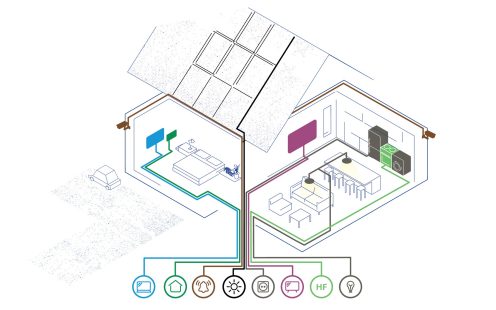

PREWIRED SOLUTIONS FOR EVERY ELECTRICAL INSTALLATION

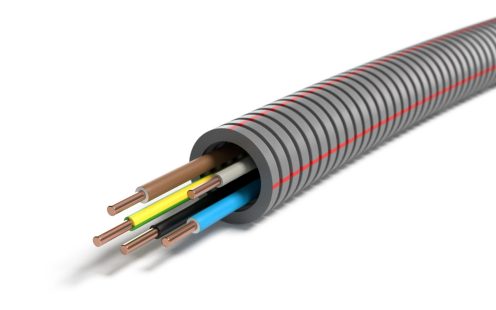

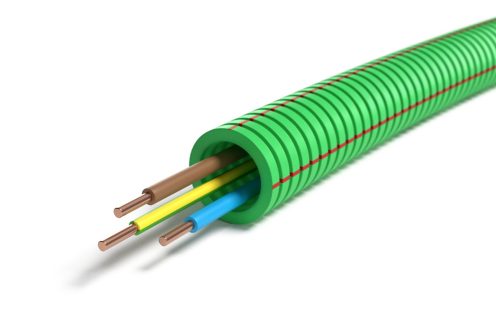

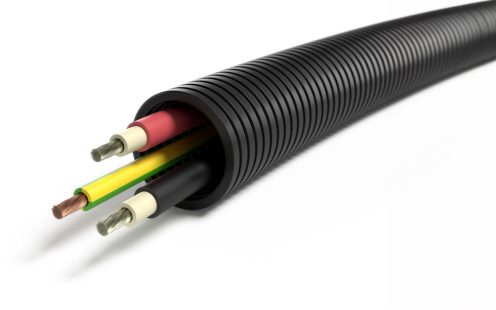

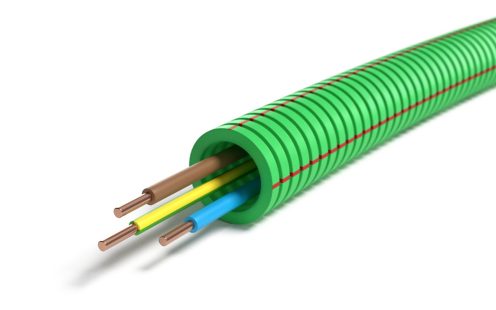

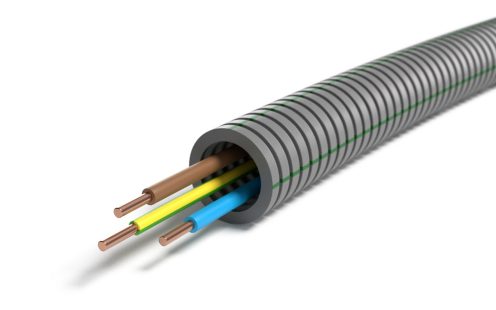

Pipelife prewired conduits are designed to make your projects faster, easier and safer. Our flexible electrical conduits not only speed up installation by eliminating wiring time, but our color-coded products ensure you reach for the right cable first time, every time.

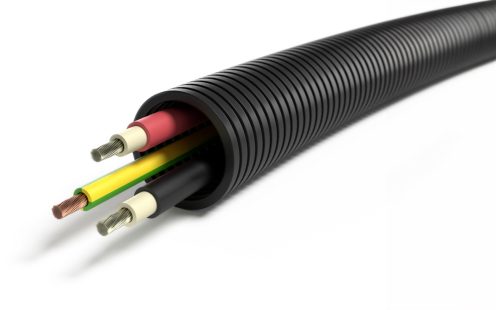

Beyond our range of conduits for every electrical need, we also offer halogen-free and UV-resistant conduits for extra safety in projects with site-specific requirements.

All of our electrical conduits adhere to the highest quality standards and comply with rigorous testing and inspection.

BENEFIT FROM PREWIRED ELECTRICAL CONDUITS

Our high-quality products have been designed to make your installations safer and easier. Discover how our diverse range of electrical conduits, fittings and wall boxes can optimize your setups.

FREQUENTLY ASKED QUESTIONS

1. HOW MUCH TIME CAN I SAVE WITH PREWIRED ELECTRICAL CONDUITS?

Our prewired conduits are engineered to simplify the installation process, eliminating tedious wire pulling. This means your team can get projects up and running faster without jeopardizing quality or safety.

Additionally, prewired conduits can help reduce the risk of errors and recalls since the wiring is done in a controlled environment before installation. This can further save time by avoiding potential delays caused by troubleshooting and fixing mistakes.

2. HOW DO COLOR-CODED ELECTRICAL CONDUITS SUPPORT THE INSTALLATION PROCESS?

Color-coded conduits help you identify the correct cable for each application at a glance. Taking time to double check you’re using the right conduit can add up over the course of an installation. However, once you associate colors to their corresponding applications, you can swiftly install the right conduit without a second thought.

This workflow also helps to quickly identify wiring errors as the offending conduit should clearly stand out as being in the wrong place.

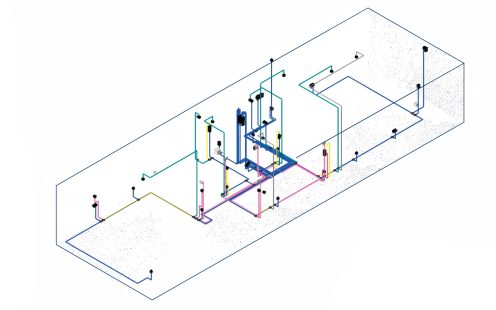

3. WHICH ELECTRICAL CONDUIT COLOR IS SUITED TO WHICH APPLICATION?

You can see a full breakdown of our color-to-application legend below:

4. HOW DO HALOGEN-FREE ELECTRICAL CONDUITS CONTRIBUTE TO FIRE SAFETY?

Halogen-free conduits do not leach toxic gases as they burn, making them much safer in the event of a fire. They also have significantly lower smoke emissions compared to other materials, which again minimizes the toxicity of the air in an already dangerous environment.

Many building codes and regulations now require or recommend the use of halogen-free materials in construction, particularly in areas where fire safety is a primary concern, such as commercial buildings and public facilities. By choosing halogen-free conduits, electricians and designers can ensure compliance with these standards and make sure their project progresses without regulatory barriers.

5. WHERE ARE UV-RESISTANT ELECTRICAL CONDUITS USED?

UV-resistant conduits are best used in outdoor applications that are regularly exposed to sunlight. This includes outdoor lighting installations, solar panels, exterior building wiring, agricultural systems, and outdoor entertainment areas.

If sun-exposed conduits are not made from UV-resistant materials, your setups can degrade over time and even risk electrical fires. With Pipelife UV-resistant electrical conduits you can rest assured your outdoor installations will remain safe and functional for at least 50 years.